Introduction:

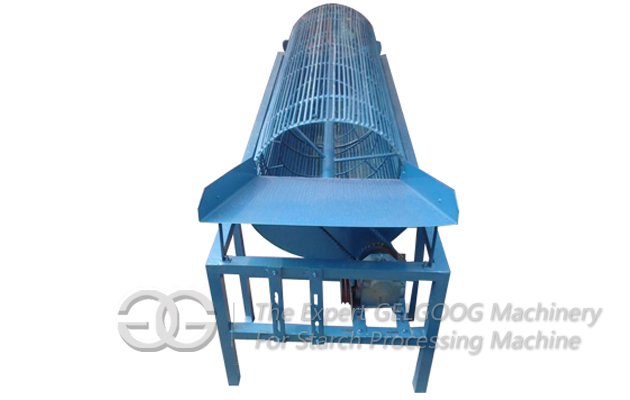

Rotary drum washer is applied to wash potatoes, cassavas, sweet potatoes and etc. Rotary washer is the washing section machine in starch processing line and it adopts the principle of countercurrent to clean out mud, sand and small stones effectively.

1.Compact design, big capacity, energy and water saving

2.Damage rate is lower than 1% to ensure the high starch extraction rate

3.Easy to installation

4.Fine quality, simple structure, easy operation, small size, small occupied area, low labor cost and energy consumption.

5.The main part of this machine is made of the special processed durable material which ensures the continuous production and it is very wear-resistant.

6.Not only applicable to sweet potatoes, but also grape, pineapple fiber more

fruit juice extracted, it has very good dewatering effect, known as the most affordable universal presser. Change machine frame, transmission system, feed section, spiral juicing, shield, through feed screw conveyor, pitch and the chan- ge of the diameter of axle etc,this machine can reach dehydration thoroughly!

The machine has the following advantages:

The rotary drum washer is mainly used in the production of starch, potato flour to wash the raw material.

The washer works according to the principle of countercurrent washing. The material flows from the inlet to the outlet along the twisted bar while the water in the rinse bath flows in the converse direction. Such movement can eliminate the sand and mud effectively.

Washing &Crushing Section

potato, the material is sent to cage washer through scrape board to get the result of decontamination, cleaningand

peeling . Then through a paddle-washing slot, material is sent to crash section.

We adopt the rasper to crash materials. Compared with traditional crasher, it has the large capacity, high starch

dissociation degree features, which are essential to get high starch recovery.

Milling and grinding section

Grinding clean potato root into cassava slurry to make it easy dewatering and drying.

Concentrating Section

The crashed material is sent to centrifugal sieve through pump to extract starch and separate potato residues.

Centrifugal sieve group are 4 or 5 stages, the front stages is to extract starch and the last stage is to dewater the

potato residues. The whole stage adopts countercurrent washing to get the best results and saving water

.

.

.